Warehouse management and inventory management are among the key areas of logistics that affect the efficiency of production and business processes. One of the tools for automating and managing warehouse processes is the WMS (Warehouse Management System).

A WMS takes care of automating and managing warehouse operations and processes, making the processes work as efficiently as possible. The main advantages of a WMS include:

- Visibility – you will always know what movements are taking place in the warehouses and also the status of the warehouses. In addition, process automation is part of the record keeping.

- Connection with readers – WMS is connected with readers, no need to deal with communication between the reader and the program, everything is done online in real time.

- Simple revaluation – if you change the price retrospectively, the new amounts can be added to the formulas with a click and everything recalculated.

- Reports – reports not only allow you to present the history in a clear way, but also help prediction

The main difference between WMS and ERP systems, which also often use warehouse process management modules, is that WMS actively manages the warehouse while ERP only records the warehouse status. Warehouse workers are equipped with display readers that communicate with the system in real time.

The WMS also offers advanced addressing of goods, such as automatic identification of bins by type of goods, and optimised loading and unloading strategies. This enables more efficient and faster inventory handling and reduces the risk of human error.

The WMS is a versatile tool suitable for all types of companies with warehousing needs, regardless of whether it is an e-furniture store a manufacturing plant with high inventory volumes or a logistics company that specializes in warehousing and distributing goods for various customers. With a WMS, these logistics service providers can track what goods they have in stock and where they are located, and can effectively plan how to distribute these goods and generate click-through documents for all necessary movements.

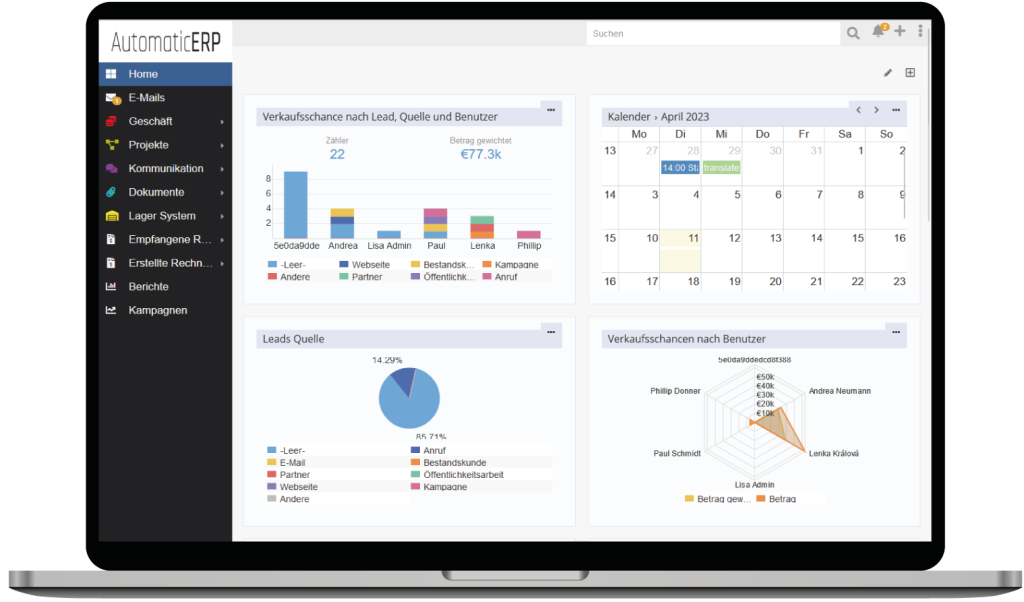

Warehouse Management System can also help with cost control and waste minimization. Businesses can track how much stock they have and how quickly goods are selling and have everything clearly displayed in reports and graphs, allowing them to plan orders for goods in line with demand. This minimises the risk of stock shortages or, conversely, overcrowding and the need to discard unwanted goods or long-term storage that takes up space to keep the warehouse running.

The digitisation of warehouse management into a WMS and the automation of many processes will ensure that errors in external (receiving and dispatching) and internal movements of goods (for example, between own warehouses) are minimised. The WMS allows you to keep track of the goods in stock, easily find specific items and prepare them efficiently for dispatch. It significantly reduces the number of incorrect duplicate or non-existent records. In conjunction with functions from an ERP or CRM system, it also provides visibility in other areas such as communication with suppliers and customers, attendance, invoices or other documents.

A properly designed Warehouse Management System will guide your company through the entire process

- Receiving goods

- Storage of goods

- Inventory management

- Manage warehouse movements

- Order picking

- Order dispatch

- Work management

- Reports and analysis

Why choose a WMS from us?

We can model and create a bespoke system, we only use the basic skeleton of the system on which we build the WMS just for you. We think about each requirement and look for ways to integrate it into the system in the best and most practical way. If your requirement is outside the standards we will offer a different solution, but we will never force you to use our solution. Specific pricing methods and custom price calculations are not a problem for us.

Part of the production of the WMS system is also working with your data, which we first go through, on their basis we build a test version into which we insert the data. We prefer agile development and that is why at the moment you already have access to the system. We are constantly improving the system and you can see everything and you can react immediately if you don’t like something or if you have another idea to add functionality.